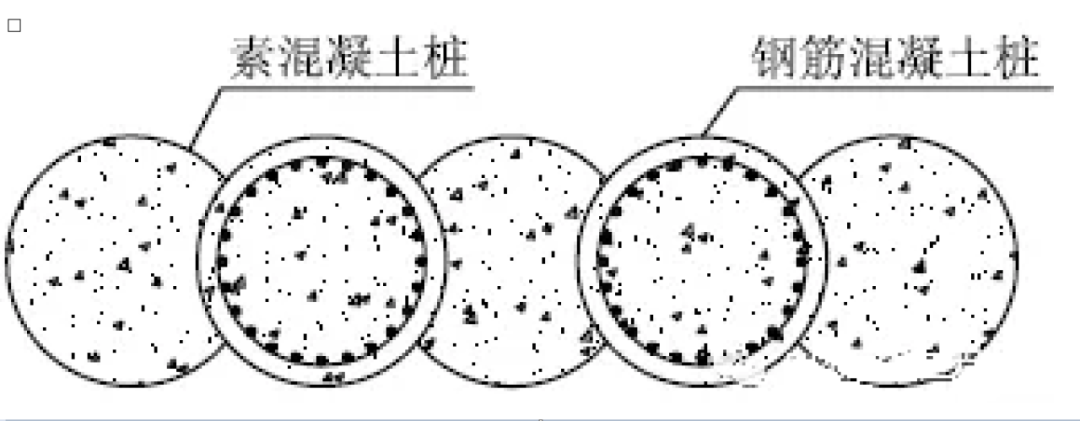

Mgbidi ikpo nke secant bụ ụdị mkpokọ nke olulu ntọala. A na-egbutu ihe ndị ahụ a gbanyere mkpọrọgwụ na ihe ndị dị larịị ma kpochie ya, a na-ahazikwa ikpo ka ọ bụrụ mgbidi nke ikpo na-ejikọta ibe ha. Enwere ike ịfefe ike nkedo n'etiti ikpo na ikpo ruo n'ókè ụfọdụ, na mgbe ọ na-ejigide ụwa, ọ nwere ike ịrụ ọrụ nke ọma nke ịkwụsị mmiri, ọ dịkwa mma maka iji mee ihe na mpaghara ndị nwere oke ala na ebe dị warara.

Nhazi nke secant ikpo mgbidi

Na tiori, n'ihi na ikpo okwu larịị dị n'akụkụ ya na mkpọmkpọ ebe ihe na-eme ka mgbidi dị n'akụkụ ya na-eme ka mgbidi ahụ pụta ìhè, ikpo ihe dị larịị na ikpo okwu siri ike na-arụkọ ọrụ ọnụ mgbe mgbidi ikpo mgbidi na-enwe nrụgide na nrụrụ. N'ihi na mesikwuru ihe ikpo okwu, ịdị adị nke larịị ihe ikpo na-amụba ya flexural stiifness, nke nwere ike na-atụle ihe nhata stiffness usoro na mgbako mgbe ahụmahụ.

Otú ọ dị, ọmụmụ nke ọrụ bara uru na-egosi na ọnụ ọgụgụ ntinye aka na isi ike nke ikpo ihe dị larịị bụ nanị ihe dị ka 15% na ọdịdị nke mgbawa na ala nke gwupụtara. Ya mere, mgbe oge na-ehulata buru ibu, a pụghị ịtụle isi ike nke ikpo ihe dị larịị; Mgbe oge na-ehulata bụ obere, stiffness onyinye nke larịị ihe ikpo nwere ike na-atụle nke ọma mgbe ịgbakọ deformation nke ikpo ahiri, na stiffness nke mesikwuru ihe ikpo nwere ike mụbaa site stiffness mma ọnụọgụ nke 1.1 ~ 1.2.

Ewu nke secant ikpo mgbidi

A na-eji ihe nwere nnukwu azụ azụ azụ n'ihu nkedo mkpọ ahụ dị larịị. The ihe intersecting akụkụ nke dị n'akụkụ larịị ihe ikpo na-ebipụ site ọnwụ ike nke casing akuakuzinwo tupu mmalite ntọala nke larịị ihe ikpo, na mgbe ahụ anụ ikpo na-awụsara na-aghọta occlusion nke n'akụkụ ikpo.

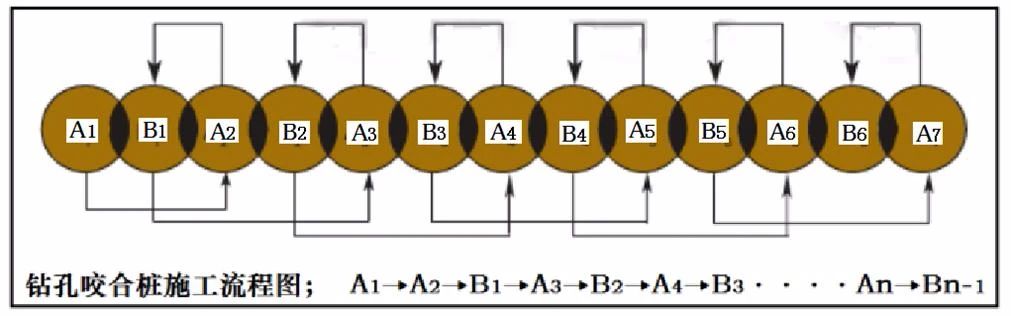

Usoro iwu nke otu secant ikpo mgbidi bụ nke a:

(a) Ngwunye nchekwa na ebe: Mgbe mgbidi nduzi nhazi nwere ike zuru oke, jiri kreen mee ka ọkpụkpụ na-emegharị ebe ahụ, ma mee ka etiti nke isi ihe na-ejide ọkpọkọ n'etiti etiti oghere mgbidi nduzi.

(b) Otu oghere oghere: Site na ịpị akụkụ nke mbụ nke cylinder nchebe (omimi nke 1.5m ~ 2.5m), ịwụ arc na-ewepụ ala site na cylinder nchebe, na-ejide ala ka ọ na-aga n'ihu ruo mgbe mbụ. A na-agbanye ngalaba nke ọma na (na-ahapụkarị 1m ~ 2m n'ala iji kwado njikọ nke cylinder) iji chọpụta nkwụsịtụ. Mgbe ịgafe ule ahụ, a na-ejikọta cylinder nchebe nke abụọ, ya mere na okirikiri ahụ ruo mgbe nrụgide ahụ ruru nhazi ikpo elu elu.

(c) Na-ebuli oghere nchara: Maka ikpo B, a ga-etinye oghere nkwado ahụ mgbe nyocha nke oghere ruru eru. N'oge a, nkwalite ọnụ ụlọ nkwado kwesịrị ịbụ nke ziri ezi.

(d) ịgba ọgwụ mgbochi ọrịa: Ọ bụrụ na mmiri dị n'ime oghere, ọ dị mkpa iji usoro ịgba ọgwụ mgbochi mmiri n'okpuru mmiri; Ọ bụrụ na enweghị mmiri n'ime oghere ahụ, jiri usoro perfusion oghere akọrọ ma ṅaa ntị na ịma jijiji.

(e) Drum na-adọba n'ime ikpo: mgbe ị na-awụsa kọntrị, dọpụta cylinder nchebe, ma leba anya na idobe ala nke ihe nchebe ≥2.5m n'okpuru ala ihe.

Usoro ịrụ ahịrị ikpo bụ nke a:

Maka ahịrị nke ikpo okwu, usoro ihe owuwu bụ A1 → A2 → B1 → A3 → B2 → A4 → B3 , na ndị ọzọ.

Ihe ngosi igodo ihe:

Mkpebi siri ike nke oge retarding nke ikpo A kwesịrị ịgbakọ oge retarding nke ikpo A dị ka usoro a si dị mgbe ị chọpụtachara oge t chọrọ maka otu ikpokọta ikpo A na B:

T=3t+K

Usoro: K - oge idobere, n'ozuzu 1.5t.

Na usoro nke oghere guzobe ikpo B, n'ihi na ihe nke ikpo A na-adịghị kpamkpam siri ike na ka na A na-eru ala, ọ nwere ike ọsọ n'ime oghere nke ikpo B si intersection nke ikpo A na ikpo B, akpụ a " ọkpọkọ ọkpọkọ". Usoro mmeri bụ:

(a) Jikwaa slump kọmpụta nke ikpo A | 14cm.

(b) A ga-etinye ihe mkpuchi ahụ ma ọ dịkarịa ala 1.5m n'okpuru ala nke oghere ahụ.

(c) Lelee ma elu elu nke ikpo A na-emikpu ozugbo. Ọ bụrụ na achọta subsidence, a ga-akwụsị ngwupụta nke ikpo B ozugbo na mgbe ị na-agbanye cylinder nchebe dị ka o kwere mee, jupụta ala ma ọ bụ mmiri n'ime ikpo B (nhazi nrụgide siri ike nke ikpo A) ruo mgbe "pipe surge" bụ. kwụsịrị.

Usoro ndị ọzọ:

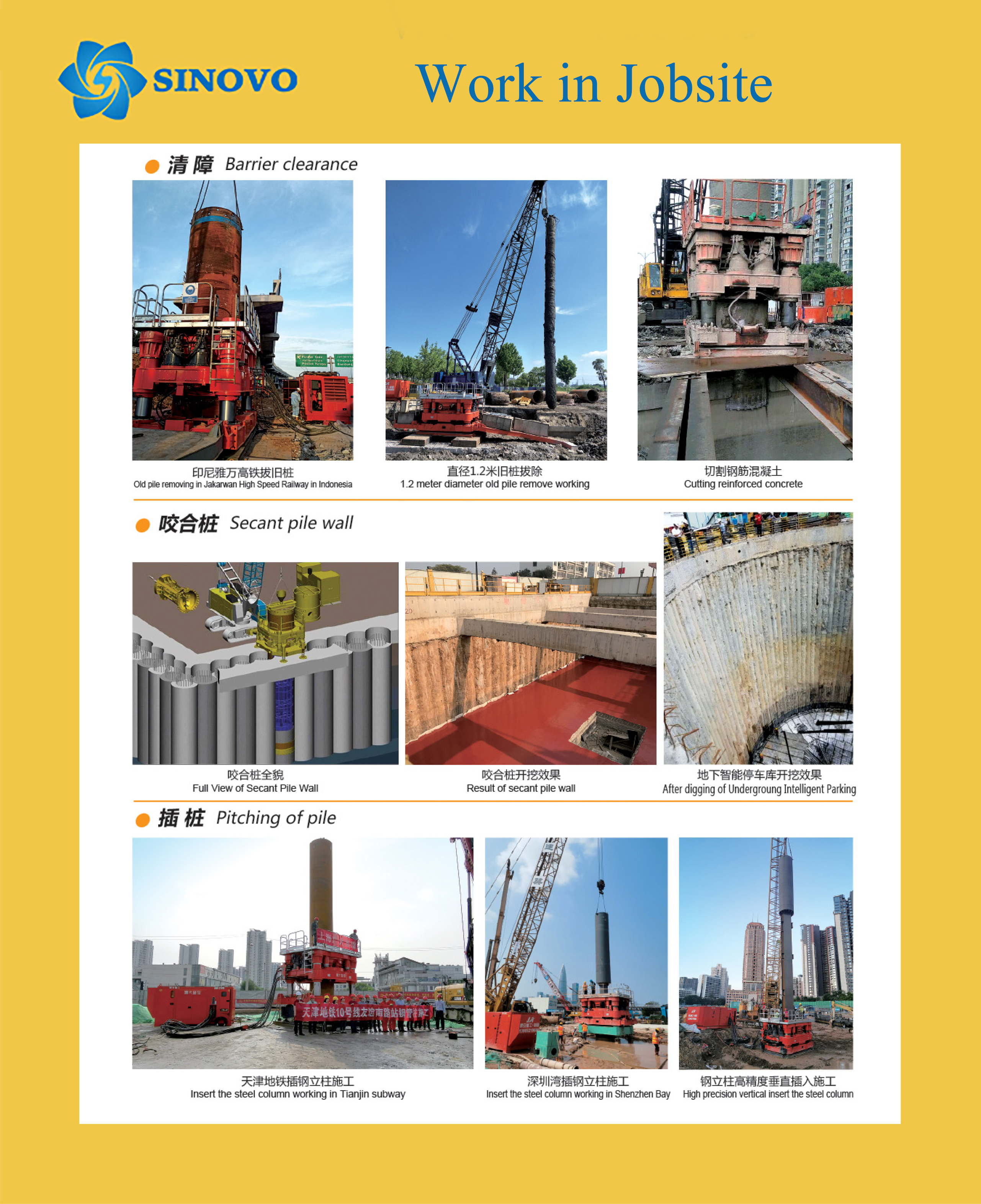

Mgbe ị na-ezute ihe mgbochi n'okpuru ala, n'ihi na mgbidi secant ikpo ọkụ na-eji mkpuchi ígwè, onye ọrụ ahụ nwere ike ibuli oghere ahụ iji wepụ ihe mgbochi mgbe ekpebisiri ike na gburugburu ebe obibi dị mma.

Ọ ga-ekwe omume iburu oghere nchara etinyebere mgbe ị na-adọpụta ihe mkpuchi ikpo elu. Mgbochi usoro nwere ike họrọ iji belata urughuru size nke ihe nchịkọta nke post B ma ọ bụ a mkpa ígwè efere ubé nta karịa onwe ya nwere ike welded na ala nke ígwè onu dịkwuo ya mgbochi-ese n'elu ike.

N'oge ewu nke secant ikpo mgbidi, anyị kwesịrị ọ bụghị nanị na-atụle ngwa ngwa mwube oge akara nke larịị ihe ikpo, ntị na-ewu oge ndokwa nke n'akụkụ larịị ihe na mesikwuru ihe ikpo, ma na-achịkwa vetikal ogo nke ikpo, ka o wee gbochie ikpo ihe a gbasiri ike ka enweghi ike ịrụ ya n'ihi oke ibu nke ike nke ikpo okwu. Ma ọ bụ n'ihi na dechara larịị ihe ikpo perpendicularity deviation bụ nnukwu, n'ihi na ọnọdụ nke ogbenye bonding mmetụta na mesikwuru ihe ikpo, ọbụna ntọala olulu leakage, enweghị ike ịkwụsị mmiri na ọdịda. Ya mere, ekwesịrị ime ndokwa ezi uche dị na ya maka iwu mgbidi nke secant, na ndekọ ihe owuwu kwesịrị ime ka ọ dị mfe ịrụ ọrụ nke ọma. Iji chịkwaa oghere na-akpụzi ziri ezi nke ikpo okwu occluding iji gboo mkpa nke imewe na nkọwa ndị metụtara ya, a ga-anakwere usoro njikwa oghere na-eme izizi. Abụọ akara ogidi nwere ike eyịride na ikpo akpụ igwe ịchịkwa perpendicularity nke elu mgbidi nke ndịda-north na n'ebe ọwụwa anyanwụ-n'ebe ọdịda anyanwụ nchebe cylinder na abụọ clinometer nwere ike iji lelee perpendicularity nke oghere. Ekwesịrị ime mgbazi na ngbanwe n'oge achọpụtara ngbanwe.

Yiri na-ewu n'okpuruala na-aga n'ihu mgbidi, n'ihi na-ewu nke n'ụzọ zuru ezu casing secant ikpo mgbidi, ọ dịkwa mkpa na-eme ka a ndu mgbidi tupu mkpọpu ala n'ime ikpo, nke afọ ojuju akara nke ụgbọ elu ọnọdụ nke gbapuru occlusive ikpo na-eje ozi dị ka. ikpo okwu maka ígwè ọrụ ihe owuwu iji gbochie oghere ahụ, jide n'aka na ikpo okwu nke mgbidi secant pile bụ nke ziri ezi, ma hụ na arụ ọrụ nke ọma nke mkpuchi mkpuchi zuru oke. Enwere ike ịhụ ihe ndị a chọrọ maka mgbidi nduzi na ihe ndị dị mkpa nke mgbidi diaphragm dị n'okpuru ala.

Oge nzipu: Nov-17-2023